Accessories

MOUNTING BRACKETS

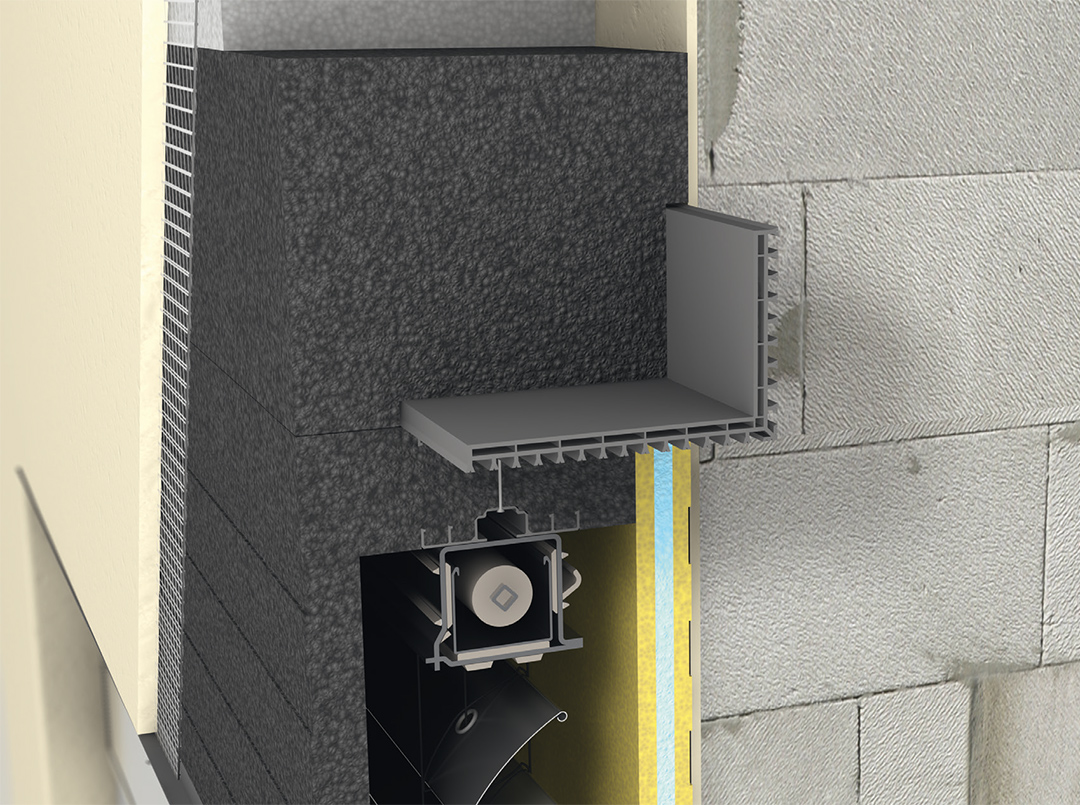

For external venetian blind boxes and CONNECTION ELEMENTS - The secure fastening for load transfer.

If external venetian blind boxes or CONNECTION ELEMENTS are integrated into ETIC systems, any loads that occur must be safely transferred into the rear masonry. The same applies to the additional fastening of the boxes. Various types of mounting brackets make this possible: The selection ranges from stainless steel brackets in different standard designs to specially manufactured variants according to structural requirements to plastic mounting brackets for a thermally decoupled system.

Made from plastic

MOUNTING BRACKETS made of plastic offer another advantage in addition to their stabilising function: the box fastening is thermally decoupled at the same time.

Stainless steel

MOUNTING BRACKETS made of stainless steel offer secure fastening with a comparatively low material thickness (5 mm). Differently arranged slotted holes and drillings enable precise alignment even in case of unevenness.

Minimum number of fixing brackets when using external venetian blind boxes in ETICS

| Box length (mm) | until 1010 | 1020 – 1400 | 1410 – 1900 | 1910 – 2400 | 2410 – 2800 | 2810 – 3800 | 3810 – 4510 | 4520 – 5010 | 5020 – 5510 | 5520 – 6000 |

| Number of angles | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

The number of pieces stated is the minimum number and must not be less than this. If the structural engineer requires a larger number, this must be complied with.