Redevelopment

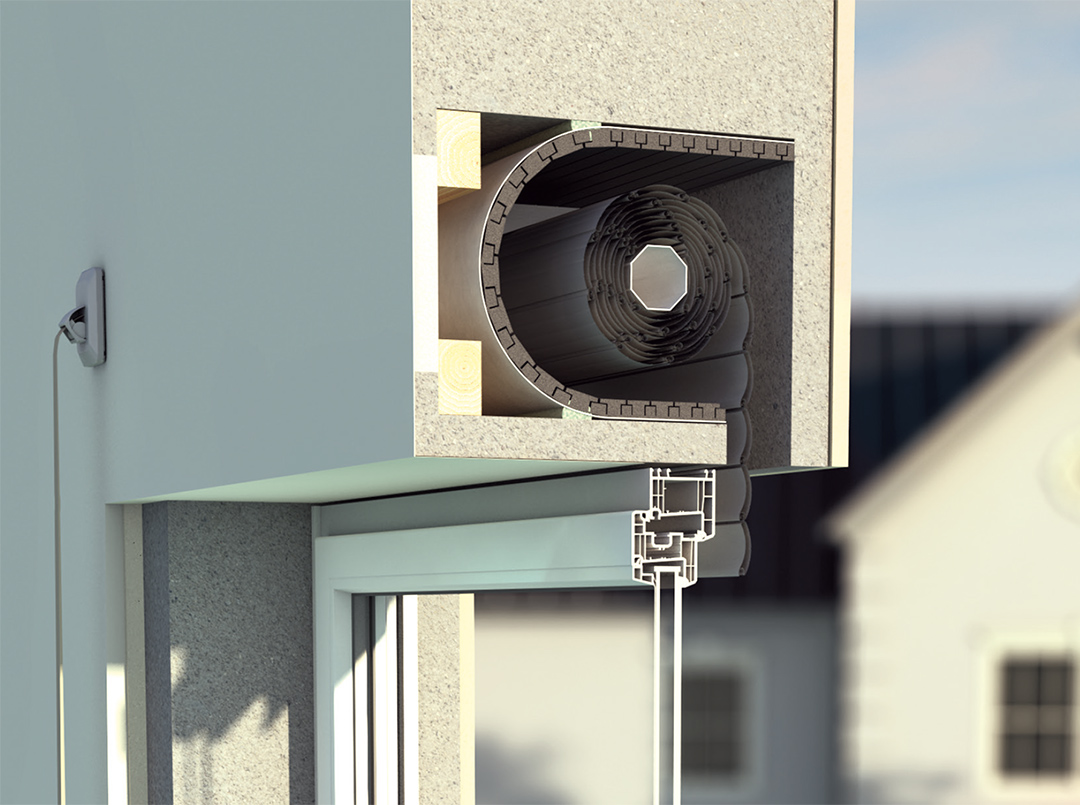

NEXT SHUTTER BOX INSULATION

An uninsulated roller shutter box is a weak point in the building envelope. In older properties, the interior is often only separated from the exterior by thin wooden or wood-based panels. This is where thermal bridges form, allowing the expensive heat to escape uncontrolled into the open air.

Beck+Heun offers a wide range of products for the retrofitting of roller shutter boxes. All systems have one thing in common: they are flexible to use and easy to install. They are made of the highly insulating and easy-to-process materials Styropor® and Neopor®.

All variants at a glance

Simple and fast to a better energy standard

THERMO-FLEX (NEOLINE)

- One-piece insulation panel for all old building roller shutter boxes

- No window change required

- No roller shutter box change required

- Easy and quick assembly

- Increased sound insulation, up to 6 dB improvement

- High flexibility

SAN-FLEX (NEOLINE)

- Two-part insulation system for all old building roller shutter boxes

- No window change required

- No roller shutter box change required

- Increased sound insulation, up to 6 dB improvement

- High flexibility

- With cover moulding for later revision work

PROFI-FLEX (VD) NEOLINE

- Two-part insulation panel system for all old building roller shutter boxes with limited space in the roller chamber

- No window change required

- No roller shutter box change required

- Easy and quick assembly

- Increased sound insulation

- With cover moulding for later revision work

THERMAL INSULATING WEDGE

- Insulation panel for PVC top-mounted roller shutter boxes

- No window change required

- No roller shutter box change required

- No painting work required

- Easy and quick assembly

Roller shutter box renovation

The easiest way to save energy

High energy efficiency

Since the introduction of the EnEV, it has been necessary to present an energy certificate when selling or renting. The use of Beck+Heun RENOVATION SYSTEMS minimises energy losses and draughts. The increased surface temperatures ensure improved living comfort and prevent mould growth1).

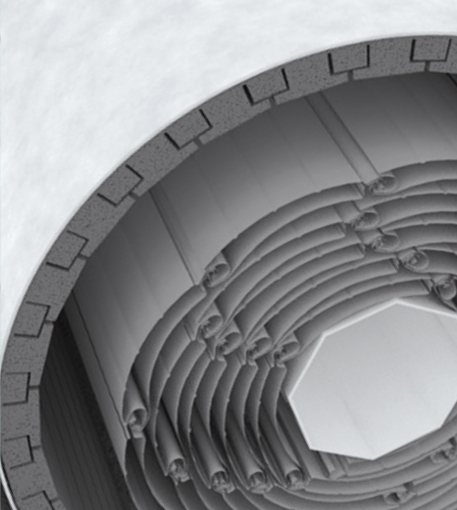

Strong insulation

For optimal realisation of the EnEV requirements, the RENOVATION SYSTEMS are available either in Neopor® [ λ = 0.032 W/(mK)] or Styropor® [ λ = 0.035 W/(mK)].

Flexible application

The RENOVATION SYSTEMS from Beck+Heun are designed in such a way that they can be easily adapted to the structural requirements, such as dimensions and shape. Depending on the scope of renovation, there are systems for box renovation alone.

Easy assembly

The materials used, Neopor® and Styropor®, are characterised by their ease of further processing. They are light and can be cut to size with a cutter knife. This means that roller shutter box renovation can usually be carried out by a single person.

Avoidance of draughts

Cold rooms and in some cases even a cold draught. Anyone who has experienced this knows how uncomfortable it is. RENOVATION SYSTEMS from Beck+Heun seal old roller shutter boxes perfectly and avoid unpleasant thermal bridges that can even lead to mould growth.

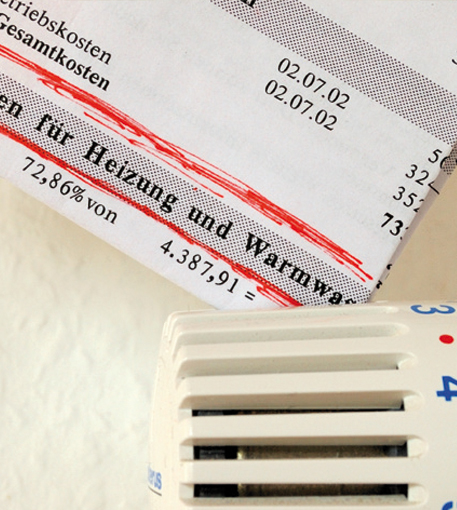

Save costs

Old roller shutter boxes offer enormous savings potential. With the Beck+Heun renovation systems, cost savings of up to 66 percent are possible in the roller shutter box area. The costs of the renovation are manageable and already pay for themselves after a short time.

Optimum sound insulation

RENOVATION SYSTEMS from Beck+Heun improve the sound insulation values of the roller shutter box by up to 6 dB. A large number of test certificates document this advantage, which is particularly evident in busy residential areas.

Side panel insulation

Additional side insulation parts are available for the THERMO-FLEX, SAN-FLEX and PROFI-FLEX systems, which must be cut to size on site. By using the THERMO-FLEX side insulation parts, additional insulation to the side edges of the roller shutter boxes is achieved.