Redevelopment

PROFI-FLEX NEOLINE

With fixed moulded parts - For boxes with inspection from the front.

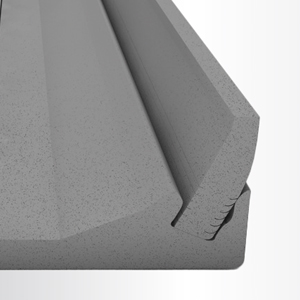

PROFI-FLEX NEOLINE was specially developed for existing roller shutter boxes with inspection opening from the front and bottom. The system consists of a height-adjustable insulation wedge for the roller shutter box and an infinitely adjustable cover moulding. Depending on the box situation, the insulating wedge is available in round or square form. This system is often used where space is limited. It is available in various designs, lengths and insulation thicknesses.

1. insulating wedge

Is always used when there is not enough room for the other insulation systems due to limited space.

2. cover moulding

The cover moulding is also equipped with predetermined interfaces. This means that it can be quickly adapted to the dimensions of the existing cover.

Neopor®

All system components are made of the high-performance insulating material Neopor® and guarantee optimum insulating properties.

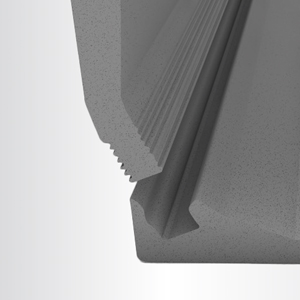

Integrated target interface

Due to the pre-designed nominal cut plates, the moulding is quickly adjustable and easy to assemble.

PROFI-FLEX-VD

In rare cases, the space in the roll space is so tight that even the insulation wedge no longer fits. In this situation, PROFI-FLEX-VD NEOLINE is used. This special solution has a shortened insulation wedge.

PROFI-FLEX NEOLINE - Variant

PROFI-FLEX NEOLINE

PROFI-FLEX NEOLINE - Dimensions

| PROFI-FLEX (NEOLINE) 1) | PROFI-FLEX NEOLINE, angular | PROFI-FLEX NEOLINE, round | PROFI-FLEX-VD NEOLINE | ||||

| A Insulation thickness | 10 | 20 | 30 | 10 | 20 | 30 | 10 |

| B Width for cover moulding | 150 – 240 | 150 – 240 | 150 – 240 | ||||

| C Total height 2) | 285 | 285 | 100 | ||||

| D Insulation thickness outside (VD moulding) | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| E Insulation thickness inside (VD moulding) | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

1) Further sizes on request

2) Adaptable through target interfaces