BUILT-IN BOXES

DRS 6 slab edge formwork

Installed in record time - plug, glue, done.

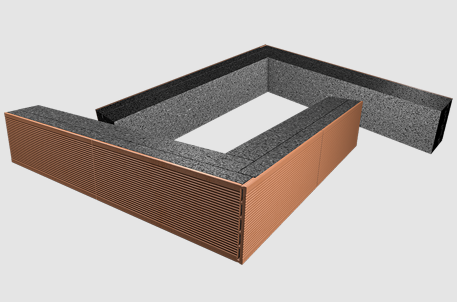

The slab edge insulating formwork DRS 6 are versatile systems for the quick and clean implementation of an external concrete slab formwork. The integrated vibration damper prevents plaster cracks. The front and rear sides can be easily moved and inserted into each other. The slab edge formwork can be formed in a very short time. Both Eurocode 6 and the Psi value of ≤ 0.06 W/(mK) required in DIN 4108 Supplement 2 are met. Due to the high demand, the range has now been expanded - from four to seven variants. This means that all types of masonry are now covered.

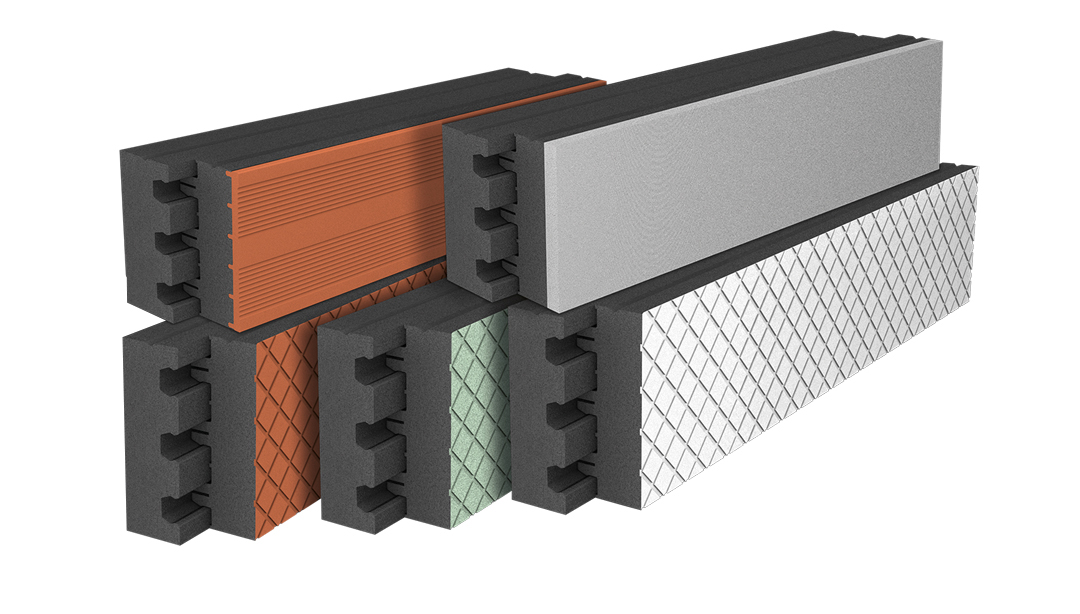

Variants and strengths

The right solution for every building situation

For all wall building materials

DRS 6 with brick facing, DRS 6 with aerated concrete or with UV coating in brick red, white or green

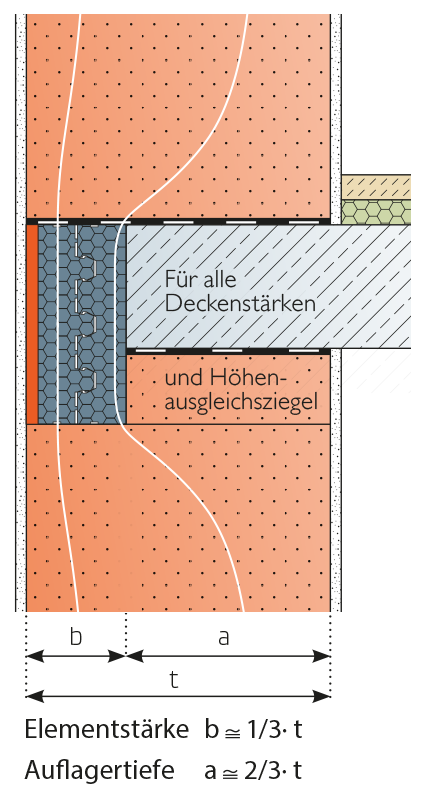

DRS 6 slab edge formwork - wall thickness/element thickness

Results, depending on masonry thickness and lambda value of the masonry.

Equivalence: ψ (Psi) in [W/(mK)] ≤ 0.06 [W/(mK)] (reference value according to Fig. 71, Bol. 2 DIN 4108): Equivalence is fulfilled.

| Thermal capacity λ :[W/(mK)] |

300 / 100 mm | 365 / 120 mm | 425 / 140 mm | 490 / 160 mm |

| 0,07 | 0,06 | 0,06 | 0,06 | 0,06 |

| 0,09 | 0,06 | 0,06 | 0,06 | 0,06 |

| 0,11 | 0,06 | 0,06 | 0,06 | 0,06 |

| 0,14 | 0,06 | 0,06 | 0,06 | 0,06 |

Length-related heat transfer coefficient Ψ :[W/(mK)]

Note: The values apply for ceiling thickness 180 mm

High-tech for the most modern standard

Warranty-proof:

Demonstrably complies with DIN 4108 with Ψ ≤ 0.06 W/(mK)

For the DRS 6 slab edge formwork made of high-quality Neopor® from Beck+Heun, the verification for Psi ≤ 0.06 W/(mK) is given. This means that Supplement 2, 2006-03 to DIN 4108 is fulfilled and therefore architects, contractors and building owners are simply on the safe side.

Fit for the future: Already complies with Eurocode 6 today

Eurocode 6 (EN 1996) will replace DIN 1053. Our DRS 6 slab edge formwork already complies with the upcoming standard. According to this, in monolithic masonry, 2/3 of the respective wall thickness should generally be used as slab bearing depth, which limits the possibility for remaining insulation. At the same time, the Psi value of ≤ 0.06 W/(mK) must still be maintained.

The DRS 6 slab edge formwork from Beck+Heun meets all specifications.

Only with us are you on the safe side!

Among all slab edge formwork, only our high-tech product DRS 6 reliably fulfils the verification Ψ ≤ 0.06 W/(mK) according to the current status and at the same time conforms to Eurocode 6. In addition, it has the best sound insulation properties and an important vibration damper with jointless insulation and short installation time!

Trust in uniquely good values for your building project!

DRS 6 slab edge formwork

Further advantages - Large in detail

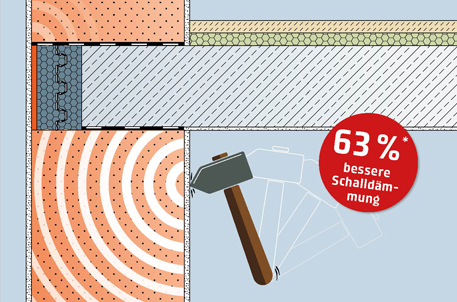

Significantly better sound insulation than conventional design

Due to the optimal butt joint insulation, the technical measurement verification for the sound insulation of our systems results in a 63 % better value than with conventional construction using ceiling edge tiles with mineral wool.

The results show that the correct slab edge formwork is important to allow as little vertical sound transmission as possible.

*According to the test report from the Institute for Noise Protection, No. 7324-13-2 of 13 October 2013.

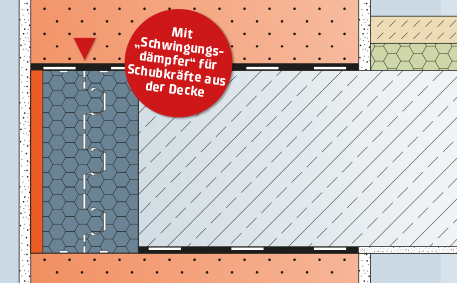

Integrated vibration damper prevents cracking

The integrated vibration damping for shear forces from the ceiling results from a 2 - 3 mm gap in the structure and from the use of different degrees of hardness in the material (outer part = PS 30 / inner part = PS 20).

Avoid thermal bridges simply and effectively

- Two-part construction of our slab edge formwork made of Neopor® λ 0.032 W/(mK)

- Jointless element connections possible by simply sliding the elements against each other

- Corner joints can also be made very easily without continuous joints.

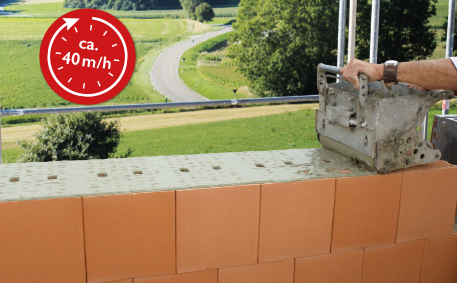

Easy-to-assemble system enables short installation times

- Our DRS 6 slab edge formwork can be fixed in just one operation

- Simply bond the formwork to the masonry with thin-bed mortar or construction adhesive.

- In just one hour, approx. 40 m of our slab edge formwork can be laid without any problems.